Automatic Sheet Feeding Botique Shopping Luxury Gift Handle Beverage Paper Bag Making Machine with Top Reinforced Card and Bottom Card Pasting in High Speed

Basic Info.

| Model NO. | ZB1200CT-430S |

| Continuous-Rolled | No |

| Layer | Single |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | Paper Bag Making Machine |

| Paper Thickness | 140g-250g |

| Glue Type | Water Soluble Cold Glue/Hot-Melt Glue |

| Transport Package | Vacuum Package & Wooden Box with Ippc Stamped |

| Specification | CE, ISO9001 |

| Trademark | ZENBO |

| Origin | China |

| HS Code | 8441200000 |

| Production Capacity | 10sets/Month |

Product Description

Boutique Paper Bag Making Machine with top card and bottom card pasting function China ZENBO

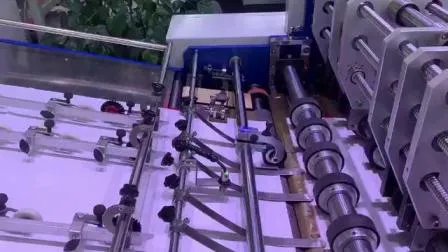

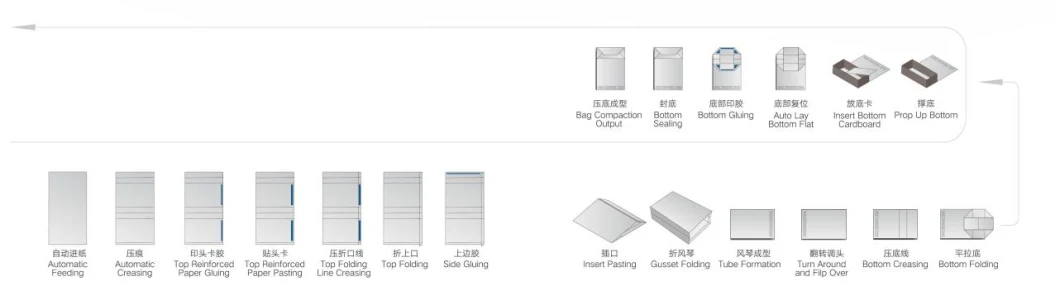

ZB1200CT-430S Automatic sheet-feeding paper bag making machine is suiable for the mass bag production, it is the first choice of medium and top grade handbag device. The product adopts mechanical, electricity, light,gas integration technology, setting a number of its proprietary technology, use sheet paper as raw material, can one-time finish; paper feeding, positioning, die-cutting, reinforced paper gluing, reniforced paper pasting, top folding, tube forming, gusset forming, square bottom folding and gluing automatic, and then compaction output, The variable speed drive technology, combined with the system of vertical and horizontal creasing, bottom folding realize trackless bag molding process. using the PLC programmable control, frequency control technology to realize the integral multi-dimensional control, more centralized control and single point remote control operating system. with characteristics of good quality and high efficiency, its technology ranks leading level in domestic similar products.1. Production description:

| Technical parameters | |

| Max.sheet (LX W) | 1200x600mm |

| Min.sheet (LX W) | 540x320mm |

| Sheet weight | 120g-250g/m2 |

| Bottom Width | 80-170mm |

| Bag Width | 180-430mm |

| Top Folding Deepth | 30-60mm |

| Top reinforced paper weight | 200-500gsm |

| Top reinforced paper length | 160-410mm |

| Top reinforced paper width | 25-50mm |

| Bottom cardboard weight | 250-400gsm |

| Bottom cardboard width | 74-164mm |

| Bottom cardboard length | 174-424mm |

| Total power | 45kw |

| Production Power | 27kw |

| Machine Size | 21500x6000x1800mm |

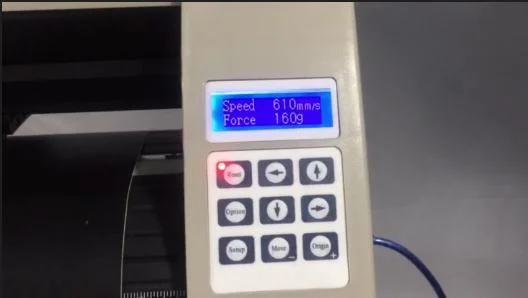

| Speed | 40-70bags/min |

| Total Weight | 20T |

| Glue Type | Water soluble cold glue (hot-melt glue) |

| Voltage | 380V |

Machine configuration

- Feeder

- Front and side guides positioning system

- Top folding system

- Both water soluable cold glue and hot melt glue

- Formation version making gusset system

- Screw rod to adjust bottom clip system

- Bottom catch bag roller paper bag fall down alert system

- Flat bottom paper bag transfer system

- Bottom cardboard inserting system

- Bottom closing and gluing system

- Automatic collection system:Automatic counting,convenient to collect bags.

Zhejiang zenbo intelligent machinery co.,ltd was established in 2009. We are professional for sheet feeding paperbag making machine. ZENBO machinery lead sheet-feeding paper bag making machine in China. We have worked with over 70% of high quality paper bag producer in China market and have 20 different types of paper bag making machine to meet the different kinds of demands for the customers. Besides, we have been exported to more than 40 countries for years.

3. Company Look

3. Certifications

4. Packing&Shipping5. Our Services.

Service and technical support including the allocation of wearing parts, online fault know, installation and debugging, the purchaser`s worker training, software upgrade, The product specification, fault repair and other buyers concerned about the contents. For example:1.offers you the how to pre-sale service? Such as: whether or not to provide the sample? Sample charges? Where the party to bear the freight?Answer: can free to provide customers with bag samples were real machine proofing proofing, and shooting videofor customer reference.Send in the proofing paper provided by the customer, the paper freight provided by the customer, to complete the sample bag proofing can be sent free of charge by our company.2.you provide the service of how the sale? Such as: supplying method of wearing parts? Delivery cycle (orders started)?Answer: the damage in the warranty period of the fittings, our company in accordance with the warranty for its freereplacement. Product delivery cycle is generally for the signing of the contract within 45 days from the date of.3.after sale service? Such as shelf life? How to provide service within the warranty period?Answer: can provide 1 years of free warranty, long-term training services (the first free, second or subsequenttraining fees), the warranty period of machine parts can be damaged According to the number of free replacement parts.4.other special services? Such as the design, customization, installation, training and other services!Answer: other services include free training for the first time, subsequent paid training, and other technical support.MACHINE INSTALLATIONFor the purchase of new machines for customers, our company can arrange engineer to install machinery and for the training of machine operators; for the second time or more need to move Machine and training services, our company provides compensation for the movement and training services.