Square Bottom Paper Bag Making Machine Produce Paper Bags

Overview Package Size 190.00cm * 210.00cm * 121.00cm Package Gross Weight 7800.000kg Mango Protection Square Bottom Pape

Overview

According to customer needs, two/ four-color printing machine, Paper bag windowing device and paper bag hand holing device or paper handle bar device can be customized.Product Parameters

Product Feature

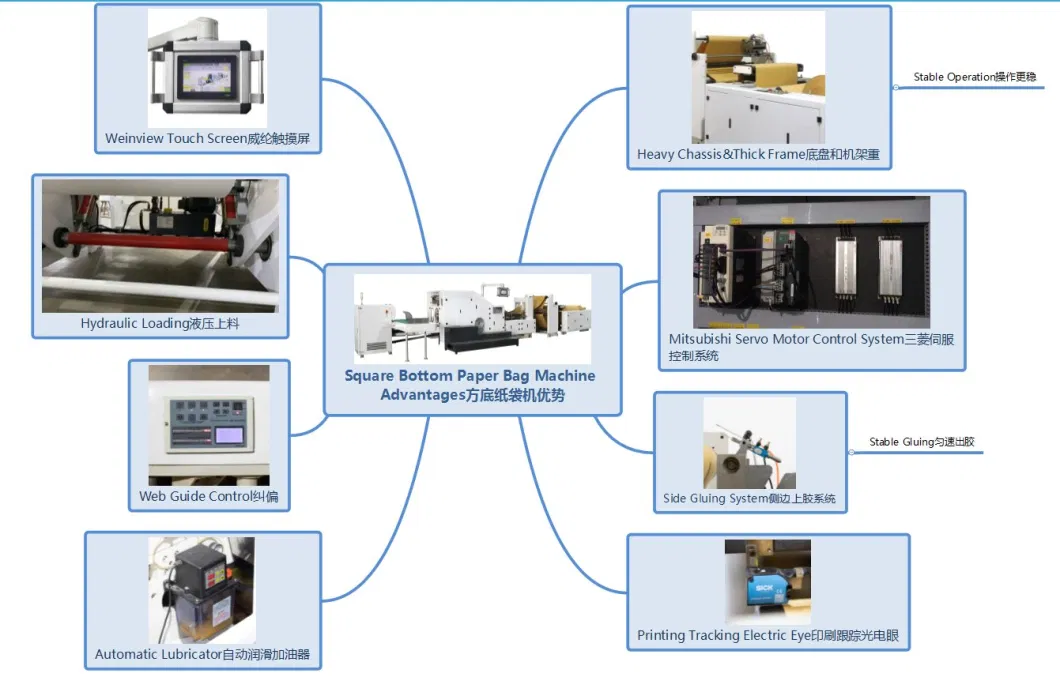

Automatic Lubricator Printing Tracking Electric Eye Web Guide Control Side Gluding System Mitsubishi Servo Motor Control SystemHydraulic LoadingWeinview Touch ScreenHeavy Chassis & Thick Frame Producing ProcessAfter Sales Service

Basic Info.

| Model NO. | XKFD |

| Bag Type | Shopping Bag |

| Characteristic | Automatic Glue |

| Computerized | Computerized |

| Speed | High |

| Width | 150-330 |

| Size and Shape | 14000*5800*2400 |

| Long | 225-470 |

| Weight | 12000kg |

| Material | Paper |

| Usage | Shopping Bag, Leisure Food Bag, Bread Bags, Fruit Bag |

| Brand | Xinke |

| Paper Bag Type | Square Bottom Paper Bag |

| Application | Food Packaging, Shopping Bag |

| Bag Length | 225-590mm |

| Pneumatic Components | Airtac |

| Printing Tracking Electric Eye | Sick |

| Paper Thickness | 60-160GSM |

| Roll Paper Diameter | 1200mm |

| PLC | Mitsubishi |

| Keywords | Paper Bag Making Machine |

| Bag Width | 150-540mm |

| Function | Paper Bag Producing |

| Automatic | Computerlized |

| Servo Motor | Mitsubishi |

| After-Sales Service Provided | Field Installation, Commissioning and Training |

| Transport Package | Packed in Wood Cartoon and Plastic Film |

| Specification | speed: 30-160pcs/min |

| Trademark | Xinke |

| Origin | China |

| HS Code | 8441200000 |

| Production Capacity | 100sets/Year |

Packaging & Delivery

Package Size 190.00cm * 210.00cm * 121.00cm Package Gross Weight 7800.000kgProduct Description

Mango Protection Square Bottom Paper Bag Making Machine Produce The Shopping Paper Bags for Market and Shopping Mall

According to customer needs, two/ four-color printing machine, Paper bag windowing device and paper bag hand holing device or paper handle bar device can be customized.Product Parameters

| Model | XKFD-220 | XKFD-280 | XKFD-330 | XKFD-450 | XKFD-540 |

| Paper Roll Length | 190-370mm (C) | 270-530mm(C) | 270-530mm (C) | 285-530mm (C) | 420-760mm (C) |

| Paper bag length | 150-320mm (L) | 225-470mm (L) | 225-470mm (L) | 225-470mm (L) | 320-680mm (L) |

| Paper bag width | 80-220mm (W) | 120-280mm(W) | 150-330mm (W) | 220-460mm (W) | 250-540mm (W) |

| Paper bag bottom width | 50-100mm (H) | 60-180mm (H) | 60-180mm (H) | 80-220mm (H) | 120-260mm (H) |

| Paper thickness | 50-130g/m2 | 60-160g/m2 | 60-160g/m2 | 80-160g/m2 | 90-160g/m2 |

| Bag Making Speed | 30-200pcs/min | 30-180pcs/min | 30-160pcs/min | 30-150pcs/min | 30-120pcs/min |

| Paper roll width | 290-670mm | 385-950mm | 445-1050mm | 630-1390mm | 770-1640mm |

| Roll paper diameter | 1200mm | 1200mm | 1200mm | 1200mm | 1200mm |

| Diameter of paper core | 76mm (3") | 76mm (3") | 76mm (3") | 76mm (3") | 76mm (3") |

| Machine power | 3phase,380v, 10kw | 3phase,380v,12kw | 3phase,380v, 12kw | 3phase,380v,15kw | 3phase,380v,18kw |

| Machine weight | 5500kg | 7000kg | 8000kg | 10000kg | 11500kg |

| Machine size | 8000x2980x1800mm | 9700x2980x1900mm | 9800x3050x1900mm | 10200x3150x2200mm | 11250x3400x2160mm |

Automatic Lubricator Printing Tracking Electric Eye Web Guide Control Side Gluding System Mitsubishi Servo Motor Control SystemHydraulic LoadingWeinview Touch ScreenHeavy Chassis & Thick Frame Producing ProcessAfter Sales Service

1.Quality Commitment: one year guarantee, Lifelong maintenance, Vulnerable parts are provided free of charge within 12 months.2. After-sales Service: 24hours online to help customer solve problem.3. Operation Guide: after the customer receives the goods, the engineer will guide the installation throughout.4. Machine Parts: all machine parts are imported from famous imported brands, which are convenient for customers to repair and buy by themselves.

Packaging & ShippingFAQ| Q: Are you a factory or trading company?R: We are a factory Q:. Why I choose your company? A: a) We are manufacturerb) We have made machine about 20 years with strong experience and advanced technology.c) Best Quality & Best Service with Competitive price.d) 100% inspection Before Shipment, and got CE certificate.e) We have Professional technical team, supply 24 hours service Q: How can we guarantee quality?R:Always a pre-production sample before mass production; Always final Inspection before shipment; |

Send to us